Now I don't subscribe to working in a sloppy fashion because of these differences, but I do realize that we are not building spaceships or nuke reactors. You have to work around each piece of wood you use. Hence, all the tight tolerences in the world will not overcome the differentials from one piece of wood to the next. Four pieces for sheers formed differently.

Two pieces for chines curved differently. While tight tolerances are a nice thought, they are not in overall evaluation a necessity when building a wood boat. As I started my build it became more clear every day that he was right. Machinists and ex machinists make the worst boat builders. When I placed a phone call to Barry for info, he informed me that Is it worth adding another plate to the wall to stiffen it up? Second deliema I can rock the entire trunion ever so little (1-2 degrees) at which time the side of the saw cabinet where the angle adjusting screw passes through flexes. Does anybody know of any other adjustment or should I remove the trunion assembly and reem out the mounting holes maybe 0.010 in to get the needed adjustment? The closest I can get the blade is still about 0.008 in out of square referenced to the miter slot. I even made myself a set of PALS to adjust the trunion.Īfter that long winded story here is the problem. Yes, I marked a reference on the blade and check it at the reference point. Rather than spend the bucks for a dial indicator I decided to set up a reference by attaching a block to the miter guage and a screw in the end as a reference point for the blade, and using feeler guages to check the runout. After reading up on it I decided to align it. I recently purchased a used Craftsman 113. If I ever reveal my Bullet you'll know why I say woodbutcher as I have lost count of the errors. Web site will assume no responsibilities for damages or injuries resulting fromĢ021 (formerly owwm.Ok I am attempting to turn over a new leaf and shed my woodbutcher persona. Good judgment and to safely operate old machinery. Themselves may not meet modern standards.

#Old craftsman table saw 113 manuals

Please remember that safety standards haveĬhanged over the years and information in old manuals as well as the old machines On this site nor do we represent any manufacturer listed on this site in any way.Ĭatalogs, manuals and any other literature that is available on this site is madeĪvailable for a historical record only. does not provide support or parts for any machines Our purpose is to provide information about vintage machinery that is generallyĭifficult to locate.

#Old craftsman table saw 113 professional

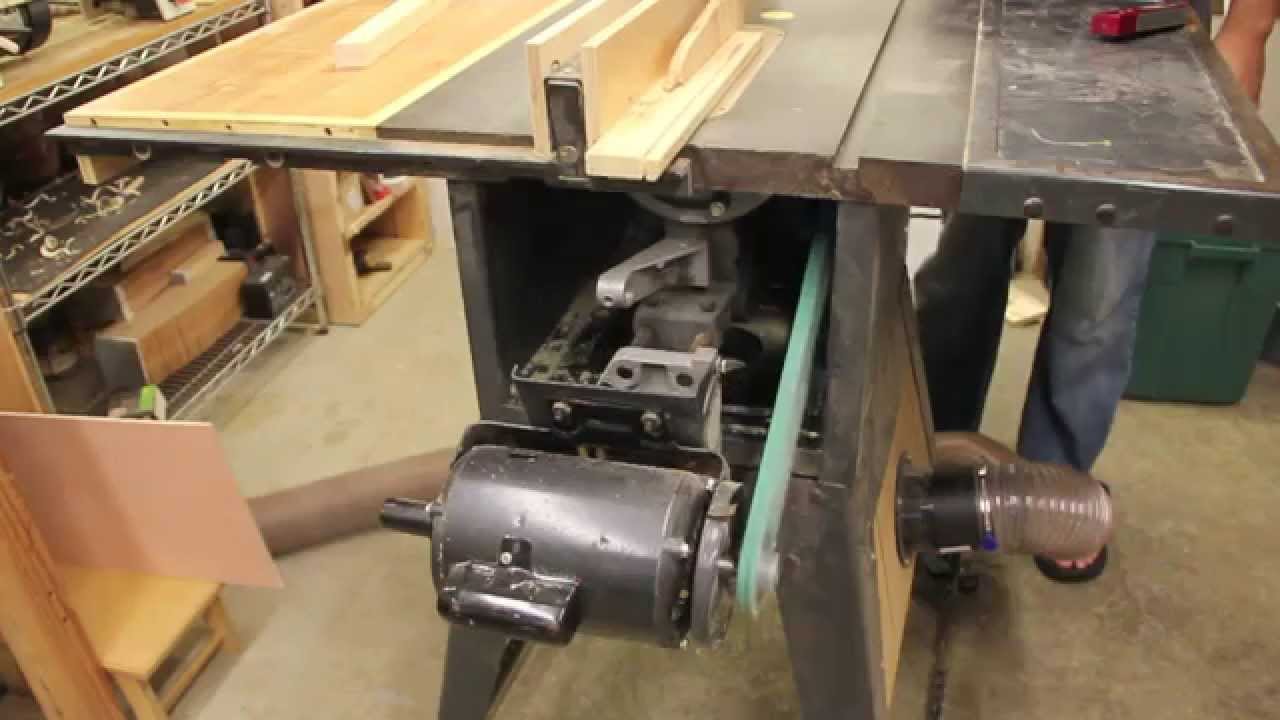

PLEASE NOTE: was founded as a public service toĪmateur and professional woodworkers who enjoy using and/or restoring vintage machinery. (Admin : deleted references the saw being built by King-Seeley. There is only one other tool on the site with the same Model No, would like to get more feedback from others with this Model #. Everything works and it came with a 10" carbide tipped blade that is on the job working as seen in the photos. The original fence and guide are with the tool but the table saw inserts are home made, machined from plate aircraft aluminum (one regular and one Dado insert). I'd like to hear from someone about the time frame this was made as the Son said his Dad bought it in 1956. The motor is an Emerson, as they do manufacture motors Motor Model 113.12170 Catalog No. It also has a step pulley on it that results in over-speed of the blade. The motor is not mounted correctly, I think to use an old drive belt that is too long, someone assembled some scrap pieces of plywood and jury rigged it to get the belt tight. The saw has a stand with it that is not related to the original saw but looks like a Sears late 70"s model table. I purchased from the original's owner's son in Youngsville, NC.

0 kommentar(er)

0 kommentar(er)